About Us

Allen & Alvan Pvt. Ltd. are the pioneer manufacturers and exporters of Builders Hardware, Cabinet and Kitchen Hardware in Brass, Zinc (Zamac), Aluminium, Steel, Copper and Bronze in several finishes including Polished Brass, Chrome, Satin Chrome, Antique, Polished Nickel, Polished Chrome and Powder Coated. Allen & Alvan was carved out of a family business in 1958 and is situated in a 9 acre plot (350,000 sq.ft.)at Talanagri Aligarh (U.P) with environment, health, safety and ethical business practices in place. Allen & Alvan 9000-2001 & 14000 ISO certified. A CE Approved and Accredited company. It strives at improving design ,durability and functional safety in products and providing the finest experience of using the Builders Hardware to customers.

Vision

The vision of Allen & Alvan is to maintain its position as a world class manufacturer of Architectural Hardware in different metals and alloys.

Allen & Alvan is recognised as the leading manufacturer of high quality, builders hardware products since 1958. Its innovation and supply of consistently high quality products has led them to winning several State and National awards including the National Export Award the highest recognition for export performance on several occasions.

Allen & Alvan is a pioneer in Door Opening Solutions, Window Fittings, Decorative Fittings as well as Cabinet Fittings. Since its inception, the company has grown by leaps and bounds, its entrepreneurial spirit and passion for making Hardware has only grown stronger. The company’s breakthroughs are evident in the exemplary quality of its forgings and die castings, as well as its electroplating process, the testing facilities could trace out the most minute traces of imperfections and improve it to achieve zero defects.

Quality Control

The quality hardware products and supply-chain solutions by Allen & Alvan have been widely appreciated in the international market, especially by top retail chains and distributors in the UK, USA, and SA.

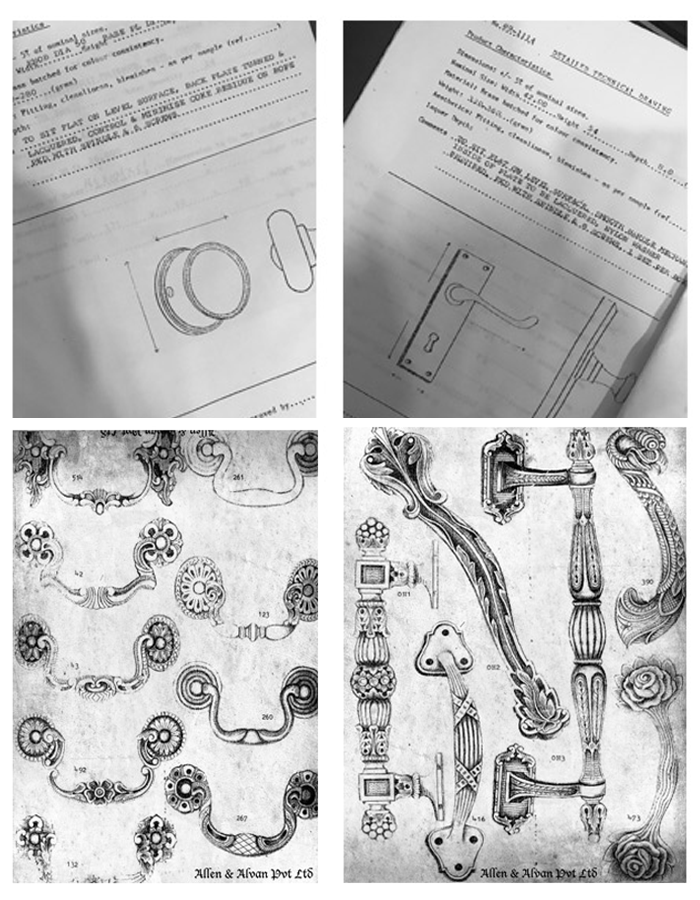

The company is constantly working towards expanding and improving its product lines and making additions to its already large range of products and finishes, which involves utilising the collection of patterns and dyes maintained by the family-run business over many generations. Recently Dhandevjit Vadra joined the business in 2012 after completing his B.Sc. in International Management from Cardiff (U.K).One can find traditional Victorian and Georgian designs at Allen & Alvan just as easily as one might find French or Italian contemporary ones, or Modern mass-produced hardware collections.

Profiles and extruded products are also tailored at the company to meet the hardware, roofing and flooring needs and specification of home builders.

Allen & Alvan has a flexible manufacturing process and can adapt to the design and samples of the customers. The company warehouse uses the best of technology and facilities to provide customers with optimum logistic and production solutions, while its design team provides them with the finest of packaging solutions.

DESIGNING

In the initial years, design at Allen and Alvan was hand made. The art of calligraphy was used where artisans made handmade intricate designs to be reproduced into products.

However, intricate the design maybe the craftsmen would draw them, reproduce on the copper plate with hammer which was then sand-casted and then finished to a pattern Goldsmiths were employed to make a pattern. Now we employ the most modern and state of art sophisticated engineering technology and equipment using VMC, EDM, Wire cut to give a near zero defect product in both engineering performance, 20 years mechanical guarantees and twenty years finish guarantees on several finishes. We have a flexible manufacturing programme in the production and can manufacture to customers designs , specification and samples.